Product

classification

conscientiously implemen

EVERY STEP

Treat every step professionally

Sales Manager:Cindy Chow

Mobile:+86 13699505501

E-mail:export@juboc.com

Sales Representative: Aviva Chow

Mobile: +86 13699505501

E-mail:monica@juboc.com

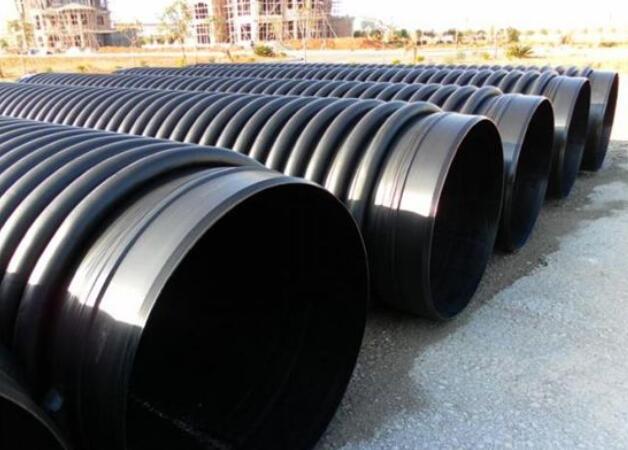

The carat tube is wrapped in a high-density polyethylene wound structure wall tube in a hot state. HDPE wound structure wall tube is made of high-density polyethylene resin as the main raw material, adopts hot-state winding forming process, and adopts polypropylene (PP) single-wall corrugated pipe as support structure to make special structural wall pipe with high resistance to external pressure.

Reachable 20KN/m²(according to customer request, SN8; SN12; SN16); Covering soil up to 20 meters

| Specification | DN300,DN400,DN500,DN600,DN800,DN1000,DN1200,DN1400,DN1500,DN1800 etc. |

| Ring stiffness | SN8; SN12; SN16 |

| Name | High quality corrugated pipe Krah pipe sn10 sn12.5 plastic hdpe Carat pipes |

| Company name | Tianjin DingRunda Group CO.,LTD |

| Service life | More than 50 year under normal condition |

Application:

1. Municipal public works

2. Nuclear power thermal power, petrochemical, mining metallurgy

3. Transportation hub, port terminal, metallurgical mining

Performance advantage

1. Good flexibility: It can adapt to the construction under poor foundation conditions and resist uneven settlement.

2. Corrosion resistance: pipeline materials are resistant to corrosion and therefore will not be corroded by oil and alkali in sewage and waste-water.

3. Good anti-seismic disturbance performance: no stress concentration will be formed at the joint, and the seismic fortification of the product will reach 9 degrees.

4. Convenient connection: simple and fast connection by socket type fused connection and socket type sealing ring.

5. Good sealing: safe zero leakage, socket-type fused connection, zero leakage

6. Anti-aging: due to the substrate characteristics of the pipeline, it can be effectively used for more than 50 years, and the maintenance cost is low.

7. Light weight: the pipe has low requirements on the bearing capacity of the foundation and is beneficial to reduce the mechanical utilization rate.

8. Wear resistance: sand abrasion test proves that the life of HDPE wound reinforced pipe is more than 4 times that of steel pipe

9. Low construction cost: light weight, easy connection, saving time and engineering costs

10. Good water performance: smooth inside, low frictional resistance, fast drainage

11. Does not pollute the environment: non-toxic, renewable raw materials, will not pollute the environment; zero leakage can prevent secondary pollution;

Complete specifications: production of DN300-DN4000 series of complete products and the realization of a fully plasticized pipe system

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q:Is the quality of your products stable?

A:The company has a complete QC system, and each batch of products will be sampled and the samples will be kept for 5 years.

Q:Can you do OEM?

A:Yes, of course. We can produce the products as per your request.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 10-15 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=5000USD, 100% in advance. Payment>=5000USD, 30% T/T in advance,balance before shipment. If you have another question, please feel free to contact us at any time.

One touch phone call, we sincerely provide 24-hour service for you~